Application

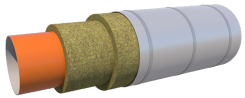

REMAK® ROCKWOOL PRI FOR PIPE LINES INSULATION

Descriptions

Remak® Rockwool mineral wool is produced from 100% natural basalt rock, its melting point is about 1350ºC. The insulation meets the strict requirements for fire safety. It is used for insulation and fire protection systems.

Remak® Rockwoool is one of the most effective fire-resistant materials. It is naturally non-combustible and possesses better fire-resistant properties than most other commonly known insulation materials

Remak® Rockwool PRI pipe insulation are manufactured by high density rock wool and available un-faced or faced with reinforced Aluminum Foil. The product is used to insulate industrial pipes with temperatures above 250ºC.

Remak® Rookwool PRI pipe does not consist of corrosive chemicals, protecting the life span of piping system, reducing maintenance costs and optimize profits for investors.

Benefits

- Outstanding insulation performance

- Easy and fast installation

- Multi-directional fiber structure helps to stabilize the coefficient of insulation and sound resistance throughout the product life.

- Good compressive strength

- Effective sound insulation and noise reduction

- Good moisture resistance, stable fiber structure, easy to cut and easy to install.

- Asbestos-free, non-toxic.

- No metal corrosive substances.

Size

Diameter range | Thickness | ||||||

mm | 25 | 30 | 40 | 50 | 60 | 80 | 100 |

13 | + | + | + | + | |||

21 | + | + | + | + | + | ||

27 | + | + | + | + | + | ||

33 | + | + | + | + | + | ||

42 | + | + | + | + | + | ||

48 | + | + | + | + | + | ||

60 | + | + | + | + | + | + | |

76 | + | + | + | + | + | + | + |

89 | + | + | + | + | + | + | + |

114 | + | + | + | + | + | + | + |

140 | + | + | + | + | + | + | |

169 | + | + | + | + | + | + | |

219 | + | + | + | + | + | + | |

273 | + | + | + | + | + | ||

324 | + | + | + | + | |||

356 | + | + | + | ||||

Specification

Specification | Sign | Unit | Description | Tolerance | Certifications | |||||||

Material | – | – | rockwool | – | TS EN 14303 | |||||||

Proportion | – | Kg/m³ | 100 – 120 | – | TS EN 14303 | |||||||

Thickness | t | mm | according to the specification table | T8* | TS EN 823 (< 150mm) | |||||||

T9** | TS EN 823 (≥ 150mm) | |||||||||||

Length | L | mm | 1000 | ± 5mm | TS EN 822 | |||||||

Inner Diameter | Ø | mm | according to the specification table | -0; +4 | TS EN 13467 (< 150mm) | |||||||

-0; +5; +2% | TS EN 13467 (≥ 150mm) | |||||||||||

Heat conductivity coefficient | Tm | oC | 50 | 100 | 150 | 200 | 250 | 300 | 350 | – | TS EN 12667 TS EN 12939 TS EN 13787 | |

100 | λD | mW/m.K | 37 | 45 | 54 | 63 | 75 | 88 | 101 | |||

> 100 | 37 | 44 | 52 | 61 | 71 | 82 | 94 | |||||

Working temperature | – | oC | 600 | – | TS EN 14707 | |||||||

Humidity | – | Kg/m² | ≤ 1 | – | TS EN 13472 | |||||||

Facing | – | – | Unfaced | Aluminum foil | – | – | ||||||

Reaction to fire Classification | – | – | A1L | A2L -S1, d0 | – | TS EN 13501-1 | ||||||

Packing | – | – | PE bag or carton box | – | – | |||||||